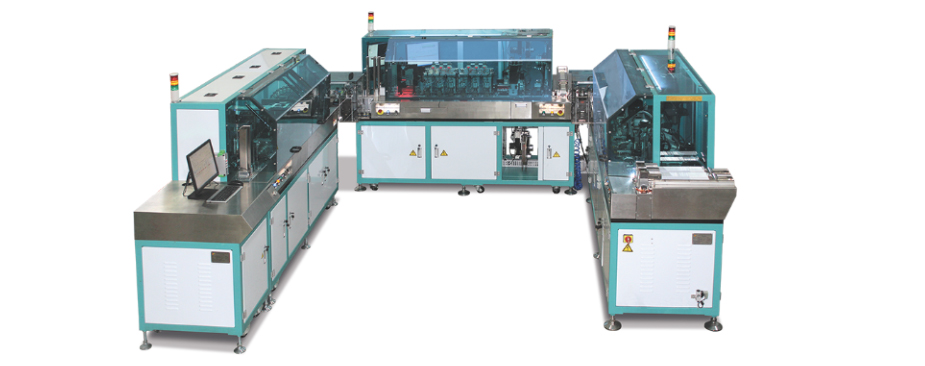

U-cell Smart Line is a new invention in the Smart Card making industry. With a master control system controls all subsystems, subsystems combination, real time production coordination, real time production monitoring, real time production QC, throughput buffer and balance can be achieved. It minimized manual work and human influence and reduced circulation, then higher efficiency, better quality and more safety can be ensured. It has been used by world leading card manufacturers worldwide.

The machines in Smart Factory can run together automatically as one line and can also produce independently.

Milling Machine station:

Card feeding conveyor × 2: each with the capacity of 500 ISO card.

Double card detection × 1: to detect accidently feed double card.

Card orientation detection × 2: color sensor to detect card direction.

Milling × 2: X-Y axis accuracy: ±0.015mm, Z axis accuracy: ± 0.015mm, flatness accuracy: ±0.005mm

Cleaning station × 2: to clean milling dust in cavity.

Card loading magazine × 2: each with the capacity of 500 ISO card.

Reject box × 1: to collect rejected card.

Chiller × 1: to provide cool water for machine.

Vacuum × 1: to suck milling dust.

Embedding Machine station:

Card transporting × 1: to transport card from milling machine to embedding machine.

Card feeding magazine × 1: with the capacity of 500 ISO card.

Double card detection × 1: to detect double card.

Cavity detection ×1: to detect if card been milled or not.

Tape releasing × 1: to release chip.

Chip punching × 1: to punch chip.

Chip embedding × 1: to embed chip.

Module presence detection × 1: to detect if the card been embedded or not.

Hot pressing × 4: to hot press embedded chip.

Cold pressing × 2: to cold press embedded chip.

Chip height detection × 1: to detect chip height.

Vision detection × 1: using OCR to detect chip embedding result.

ATR detection × 1: to detect ATR.

Card loading magazine × 1: with the capacity of 500 ISO card.

Reject box × 1: to collect rejected card.

Chiller × 1: to provide cool water for machine.

Personalization Machine station:

Card transporting × 1: to transport card from embedding machine to personalization machine.

Card feeding magazine × 1: with the capacity of 500 ISO card.

Double card detection × 1: to detect accidently fed double card.

Card direction detection × 1: a color sensor to detect card direction according to different color.

Chip personalization barrel with 32 readers for ISO card x 1: Mingsen reader. When encoding, there are 32 ISO cards been personalized inside the barrel. When encoding 2 chips in 1 card, there are 16 cards inside the barrel.

Card flip-over × 1: to flip-over card.

Laser No.1: a Mingsen HS 50W fiber laser and smog filter to do laser graphic printing.

OCR (Optional) × 1: to check laser printing result, failed card will be rejected.

Card flip-over × 1: to flip-over card.

Laser No.2: a Mingsen HS 50W fiber laser and smog filter to do laser graphic printing.

OCR (Optional) × 1: to check laser printing result, failed card will be rejected.

Card flip-over × 1: to flip-over card.

Vertical card collecting magazine with the capacity of 500 ISO card x 1

020-37094830

020-37094830